Compressor Rebuild

Compressors are the heart of the refrigeration system. They are the most complex components in the refrigeration cycle, which is why it’s critical to troubleshoot compressor issues quickly and get customers back online.

Vibration Analysis

With advances in vibration analysis technology refrigeration screw compressor applications, the industry standard of rebuilding compressors based on hours is no longer the most cost effective way to maintain the integrity of your screw compressor. Periodic monitoring of your screw compressor and motor with vibration analysis requires no down time and allows you to predict the condition of the bearings. As the bearings begin to develop defects, a compressor overhaul can be scheduled based on the actual condition of the bearings, not the operating hours. Vibration analysis can extend the life of the compressor without compromising its reliability.

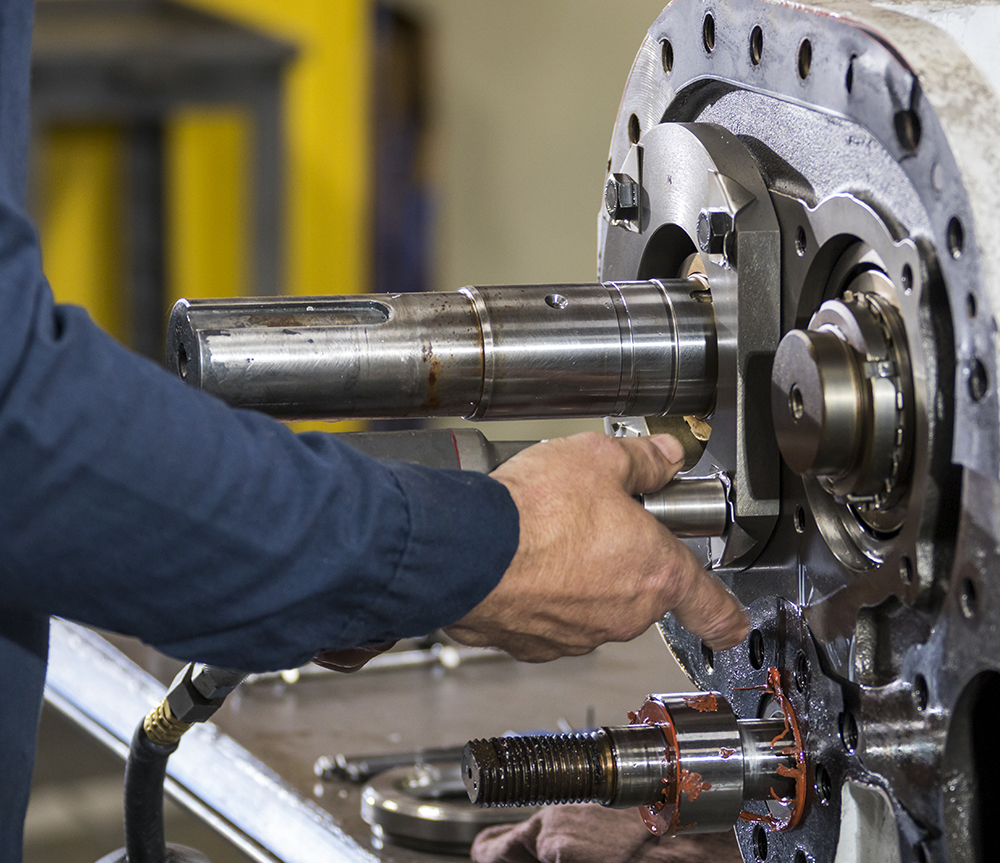

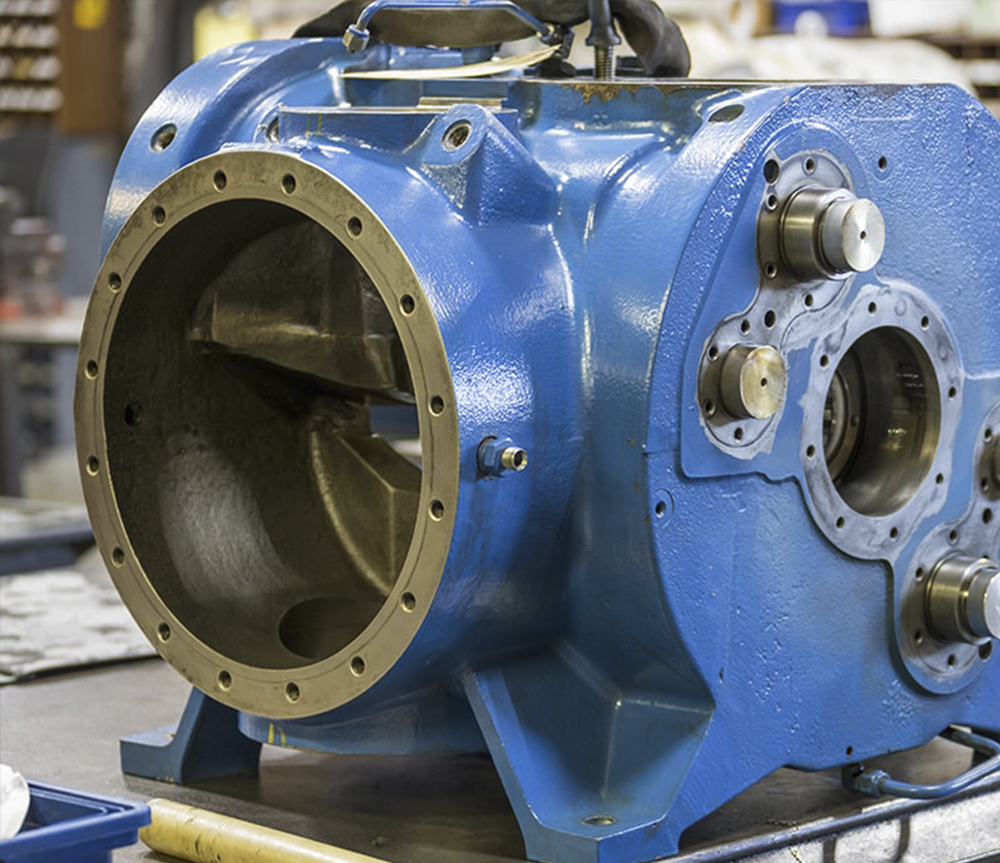

When a Compressor is Rebuilt

We use OEM parts, and all compressor rebuilds are completed by factory certified and supported technicians. We work within specific time frames and respond promptly to emergency situations.

Before any rebuild, we evaluate why the compressor needs to be overhauled. We look for the causes of premature failure and work with customers to get those problems resolved before the newly rebuilt compressor is installed. We want to ensure they get the most life span out of our overhauls.

APCCO’s reports include complete before and after pictures of each overhaul as well as documentation of the package service and start-up.